Really can't gush on this post, can't go on and on about the joys of plumbing and indoor running water and flushing toilets. It really is NOT glamorous, exciting, adrenaline rushing or remotely interesting at all.

But nevertheless in the name of full disclosure and just because I went to the trouble of taking the pictures I will share this momentous milestone with all of you.

The plumbing has proved to be a challenge as all the 'water' appliances are in the container side of the house and having sandwiched two containers together we don't have the luxury of an interior wall to chase plumbing pipes through. Hence there were a few renditions of the plan but Kyle finally came up with a layout that fit the house, that we could work with, with the finished look of the house and most importantly a plan that the County Inspector signed off on.

We needed to get all the plumbing pieces installed before we could have the spray foam insulation applied as it would be a huge ordeal to cut through it after the fact to run the plumbing through both in the walls of the exterior of the container and underneath the containers. Kyle also ran all the conduit for the electric underneath the containers so all we need to do is run wire to connect the dots.

The other thing we needed to do before we could even put most of the plumbing and electric in was to clean up the underneath of the containers. Sounds easy enough, it is cleaning........WRONG!

THIS WAS THE MOST DISGUSTING JOB AS OF YET ON THIS HOUSE BUILD. Did you hear me, DISGUSTING.

It involved laying on my back on one of those wheeled boards that car mechanics use with a metal grinding wheel in hand, eye glasses, gloves, a face mask, a face shield in 90+ degree weather and on the second go around, a doo rag as it took me days to get the rust pieces out of my hair. Grinding the rust off the underneath the containers was miserable. It went everywhere, in every crack, nook and cranny. I came out from that 2' crawl space each time covered head to foot in brown filth, I was filthier than any time from the horse days. So glad that, that job is behind me and done and the black widow spider was relocated (to the vacuum).

Anyway, onwards and upwards after buying about 200+ plumbing elbows, turns, angles, connectors, reducers and multiple other parts and pieces that seemed to have no name but all come in black ABS plastic.

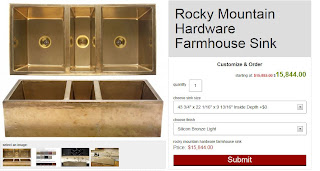

It is tricky to plan the venting for every single toilet, sink, shower etc..and how they can all tie into one another so your roof doesn't look like swiss cheese. This one above is for the kitchen, overcoming the venting code to maneuver around the window directly above it.

This is the downstairs bathroom for the sink, toilet and shower. We lucked out here because of the site built wall between the bathroom and laundry room directly behind it.

This is the master bathroom, difficult to overcome some challenges here as there is the structural red iron on the exterior of the house that we cannot drill through so took some ingenuity on Kyle's part. And again the window issue above the sink came into play. This design resulted in some unique design finishes that we came up with so stay tuned for that down the road.

This takes the downstairs bathroom vent up to the roof. This runs through the master closet and will get chased out.

Drainage from the master bathroom shower (above) and toilet (below) that come down into the utility room and back hallway, respectively and the hallway will get chased out.

Our clean-out, the final chase design will provide a small broom closet here that will allow access to the clean-out.

So once all the plumbing and venting network is in place the openings to the fixtures get covered up and then the entire system gets filled with water to ensure that there are no leaks. Here is Kyle filling the whole system from the roof top. It was actually kind of fun and SUCCESS first time. Way to go baby, nice planning and install. Who needs a plumber and we have INDOOR plumbing. It was all worth it.

And a moment to appreciate the nice view a the end of it all. Phew.....now on to the next thing - insulation!